In the ever evolving world of industrial manufacturing, fiber laser cutting machines have quickly taken center stage. They are known for their high precision, faster cutting speed, and energy efficiency. Unlike traditional cutting methods, these machines rely on a powerful laser beam transmitted through fiber optics. This technology delivers clean cuts with minimal heat, reducing material distortion and saving time. But not all fiber laser cutting machines are the same. Depending on your application, material type, and production volume, you may need a specific category. In this blog, we break down the main types of fiber laser cutting machines and explore how each one fits into modern manufacturing.

1. Flatbed Fiber Laser Cutting Machines

1. Flatbed Fiber Laser Cutting Machines

Flatbed or sheet fiber laser cutting machines are the most commonly used. These are designed to cut flat sheet metal like stainless steel, aluminum, carbon steel, and brass. What makes flatbed models so popular is their versatility. They can handle complex shapes, fine details, and various thicknesses. Many flatbed systems also come with automatic loading and unloading systems, which improves workflow and reduces downtime. These machines are ideal for industries such as automotive, signage, kitchen equipment, and general metal fabrication.

2. Fiber Laser Tube Cutting Machines

While flat sheets are common, many manufacturers also need to process tubes and pipes. That’s where fiber laser tube cutting machines come into play. They are designed to cut round, square, or rectangular tubes with precision. This type is especially useful for industries that manufacture furniture, fitness equipment, construction frames, and agricultural tools. Some advanced models even handle both flat sheets and tubes, offering maximum flexibility. Moreover, these machines reduce the need for secondary operations like drilling or notching. The laser can cut holes, slots, and custom patterns in one go.

3. High Power Fiber Laser Cutting Machines

For thick metals or high-volume production, high power fiber lasers (6kW and above) are the go to option. These machines can cut through thick plates while maintaining clean edges and high accuracy. Because of their power, they are often used in heavy duty industries such as shipbuilding, aerospace, and steel fabrication. They also support high speed operation, allowing manufacturers to keep up with large orders without sacrificing quality. Although they require more investment, their productivity justifies the cost in the long run.

4. Enclosed or Fully Covered Fiber Laser Machines

Safety and cleanliness are top priorities in many production environments. Enclosed or fully covered fiber laser machines are built with protective housings to contain laser radiation, sparks, and dust. These machines are often equipped with fume extraction systems. They are ideal for businesses with safety compliance standards or working in enclosed workshops. Besides protection, they offer a quieter and cleaner cutting environment, which improves operator comfort and machine longevity.

5. Entry Level Compact Fiber Laser Cutters

Not every business needs a massive, high powered laser system. For small shops, hobbyists, or startups, compact fiber laser machines are a great entry point. These systems often come in tabletop or mid sized formats and support cutting of thinner materials. They are easier to maintain, cost less to run, and require less floor space. In fact, many businesses start with a compact model before scaling up to larger systems.

How to Choose the Right Type

Now that you’ve seen the different categories, choosing the right fiber laser cutting machine depends on a few key factors:

– Material type and thickness

– Daily production volume

– Available space in your facility

– Budget and future scalability

Each machine has its strengths. Flatbed machines are great all rounders, while tube cutters add specific capabilities. High power models handle heavy-duty tasks, and compact systems are perfect for beginners. If you’re not sure where to start, speaking with an expert can help you understand which machine fits your workflow best.

The Shift from Conventional to Fiber Laser Cutting: A User’s Perspective

In the past, metal fabrication shops heavily relied on conventional cutting methods such as plasma cutting, waterjet systems, or mechanical saws. While these tools got the job done, many users found them slow, noisy, and expensive to maintain. Over time, as projects demanded tighter tolerances and faster turnarounds, the need for a more efficient cutting process became impossible to ignore.

That’s when fiber laser cutting machines entered the picture. Unlike older methods, fiber lasers offer high-speed cutting, clean edges, and minimal post processing. At first, many users hesitated. Transitioning from decades old equipment to advanced laser systems felt like a big leap. However, once they experienced the benefits, very few wanted to go back.

From a user’s perspective, the most noticeable change is time. What once took hours now takes minutes. Moreover, fiber laser cutting machines handle a wide variety of materials and thicknesses, making them more flexible for diverse projects. Additionally, operators noticed reduced downtime due to fewer consumables and minimal calibration. Beyond speed, users report increased accuracy. Since the laser beam is focused and stable, it ensures clean, precise cuts every time. In fact, many fabricators have improved their output quality without increasing overhead costs.

To sum it up, users who moved away from conventional tools toward fiber laser cutting machines consistently highlight efficiency, reduced waste, and long-term cost savings. As demands grow, so does the need to stay competitive, and fiber lasers clearly offer that edge.

Hidden Costs Saved by Fiber Laser Machines

While upfront costs may seem high, many manufacturers quickly realize that fiber laser cutting machines offer savings in places they never expected. Traditional cutting systems often require frequent maintenance, more consumables, and larger teams to manage manual tasks. These hidden costs build up over time.

In contrast, fiber laser machines operate with less wear and tear. They don’t rely on gas mixtures like CO2 lasers or blades that dull with use. As a result, users spend less on replacements, servicing, and labor. Moreover, downtime drops significantly since fiber lasers are designed for long, uninterrupted runs. Additionally, cleaner cuts mean fewer reworks. This not only saves materials but also frees up operator time for other projects. Businesses can complete more orders using the same resources, which directly improves profitability.

Energy efficiency is another overlooked benefit. Fiber laser systems consume less power than older technologies. Over months, this translates into lower utility bills, a quiet yet powerful saving. All things considered, fiber laser cutting machines pay for themselves faster than most expect. These hidden advantages make them a smarter long term investment for small and large workshops alike.

Operator Centric Design: Making Fiber Laser Machines Easy to Run

Modern day fiber laser cutting machines are not just about power, they’re also built for people. Unlike traditional machines that required constant manual adjustments, today’s systems are designed with the operator in mind. For instance, most machines now feature intuitive touchscreen interfaces. As a result, even new users can learn to operate them with minimal training. Additionally, many systems support remote control access, allowing technicians to monitor processes from a distance. This proves especially helpful for facilities managing multiple machines at once.

Moreover, daily maintenance tasks have become simpler. Access panels are easier to reach, cleaning cycles are automated, and alerts notify operators before an issue escalates. That means less time spent troubleshooting and more time cutting. What’s also worth noting is how these machines reduce fatigue. Lower noise levels, smoother operation, and automated loading systems all contribute to a better working environment.

Ultimately, these user friendly features empower teams. Rather than fearing complex controls, operators now feel more confident and efficient. And when workers are more productive, the whole operation benefits. So, it’s clear, fiber laser cutting machines don’t just enhance cutting results. They also redefine how teams interact with technology on the shop floor.

Customization Trends in Fiber Laser Cutting Machines

As industries evolve, one size fits all solutions no longer work. That’s why modern fiber laser cutting machines are now built with customization in mind. Manufacturers today want machines that not only cut precisely but also align with their specific production needs. To meet this demand, machine builders are offering modular designs. With these, businesses can choose add-ons like automatic tube loaders, dual exchange tables, or even hybrid cutting heads. This allows small shops and large factories alike to tailor machines based on volume, material type, and product complexity.

Furthermore, integration with CAD/CAM software has become more flexible. Instead of adapting to rigid systems, users can now work with platforms they already know. This transition boosts productivity while minimizing downtime during training. Another trend is industry-specific configurations. For example, furniture manufacturers often need edge-cleaning attachments, while automotive plants require tighter tolerances. So, machines now come equipped to handle such niche tasks right out of the box.

What’s more, with the rise of IoT enabled features, operators can track performance and schedule maintenance based on real time data. All of this means businesses no longer need to compromise. In short, customization isn’t just a bonus, it’s becoming standard in fiber laser cutting machine technology.

Environmental and Safety Improvements in Modern Fiber Laser Cutting

In today’s industrial landscape, efficiency isn’t the only goal, sustainability and safety matter just as much. Thankfully, fiber laser cutting machines have evolved to meet these growing concerns without compromising performance. First, fiber lasers are far more energy efficient than older technologies. They consume less power during operation, which directly reduces a facility’s carbon footprint. This not only lowers energy bills but also aligns with global efforts to cut emissions.

Moreover, fiber lasers generate less waste. Since their cuts are cleaner, there’s less scrap material to discard. Additionally, many systems now include fume extraction units that capture and filter smoke or dust created during cutting. This keeps the air in workshops healthier for operators. From a safety standpoint, things have also improved. Enclosed machine designs protect users from exposure to high-intensity beams. At the same time, modern sensors detect hazards before they become serious, shutting the machine down automatically if needed.

Noise levels have dropped, too. Compared to plasma or mechanical cutters, fiber lasers run quietly, creating a calmer workspace for the team. All in all, fiber laser cutting machines today aren’t just smarter and faster, they’re also safer for people and better for the planet.

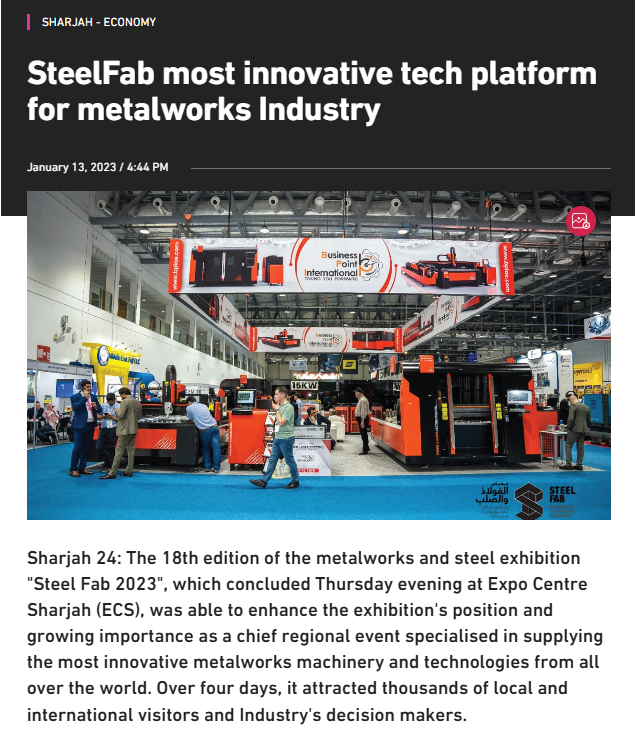

About SteelFab 2023 Exhibition For Metalworks Industry

SteelFab continues to be a global platform that exhibits the latest metal fabrication machinery. Business Point International, UAE is honored to be part of SteelFab 2023, presenting our advanced fiber laser cutting machines. This event provided the perfect opportunity to engage with industry professionals, share ideas and showcase our precision in the metalworking industry. Our presence at SteelFab proves our role in supporting industrial innovation and delivering machinery to meet today’s demanding fabrication needs.

SteelFab Event Highlights (2019 – 2025)

SteelFab 2019 – Exhibited our metal fabrication machines and high-speed fiber laser cutting machine. Watch the highlights: [https://youtu.be/QWVEXlSJVCc]

SteelFab 2020 – Showcasing advanced fiber laser cutting machine. Check it out: [https://youtu.be/RFrPcK-oNYo]

SteelFab 2022 – A stage for revolutionary metal processing machines and modernized fiber laser cutting machine. Watch here: [https://youtu.be/Uc8AufxYbGI]

SteelFab 2024 – Bringing together metal fabrication industry leaders and technology pioneers. Experience it here: [https://youtu.be/OM5jt_iJzfQ]

SteelFab 2025 – The future of fiber laser cutting machine and metal fabrication unfolds. See the event highlights: [https://youtu.be/JI1rplS7uDI]

Why Fiber Laser Cutting Machines Are the Future

As industries demand faster turnaround times and higher precision, fiber laser cutting machines are emerging as the clear choice. They’re not just a passing trend, they’re setting a new benchmark for what cutting technology should deliver. Over time, manufacturers have realized that switching to fiber lasers brings more than just speed. The machines improve consistency, reduce operating costs, and offer room for custom setups. From thin sheets to thick tubes, they handle a wide range of materials with ease. That kind of flexibility is hard to ignore.

At Business Point International, we understand these evolving needs. That’s why we offer a range of high performance fiber laser cutting machines tailored for UAE industries. Whether you’re a small fabrication unit or a large scale manufacturer, we have the right machine and the local expertise to support your growth. Plus, with strong after sales support and genuine parts always available, we’re more than a supplier, we’re your long term partner. To conclude, fiber laser cutting machines aren’t just machines, they’re strategic assets. And with Business Point International by your side, upgrading to smarter, faster, and more efficient cutting has never been easier.