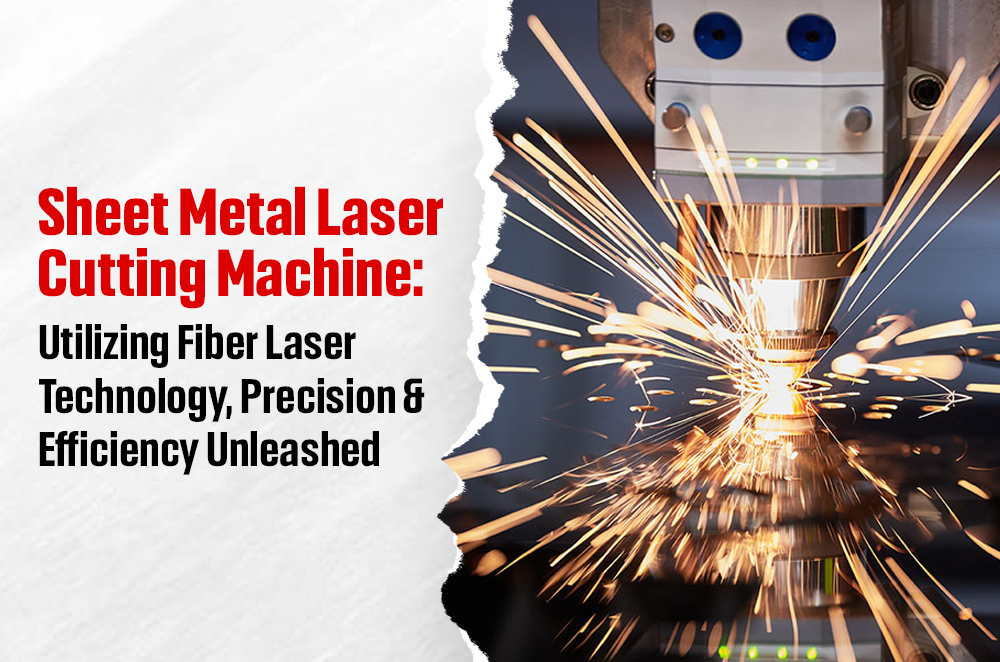

The sheet metal laser cutting machine is providing precise material processing, giving the essential aspects of fabrication in the manufacturing sector. The advanced technique of metal fabrication is the fiber laser cutter. It is suitable for cutting pieces of sheet metals, tubes, pipes and profiles. The fiber laser cutting machine is a thermal cutting process involving beams of laser on the workpiece to melt or vaporize the materials until the desired shape from the material is obtained. This technology is one of the most effective for cutting sheet metal. This article provides essential information regarding laser cutting before utilizing it. Let’s get right into it.

What Is A Sheet Metal Laser Cutting Machine?

The manufacturing processes are critical for the cutting, processing and modification of materials for part fabrication. It is one of the standard methods for cutting and removing components from a working piece to the final end product. The technique involves cutting out pieces by using fiber laser beams.

The laser cutting technique runs with the computer numerical control (CNC) technology which accounts for impeccable precision and accuracy. Before the CNC cutting or laser cutting operation, the operator must have input codes or detailing designs or patterns into the computer which makes it difficult to deliver the output. Laser cutting involves using laser beams to melt the materials thereby causing smooth & sharp cuts. It consists of two operations working. The first involves the material absorbing the focused laser beam to cause the cut. The second involves the cutting nozzle and producing the process gas required for the cutting. Protects the processing head from splashes and helps remove excesses from the kerf.

The sheet metal has the ability to be cut very effectively by laser cutting and is the most effective choice for many sheet metal projects. The modernized method provides benefits that cannot be obtained from other methods. It is important to compare the capabilities of the machine to the project’s requirements when selecting a process for the metals.

The sheet metal laser cutting machine cuts the material that ensures accurate output without the expense or time of further subsequent or secondary processing. It is ideal for cutting carbon, stainless steel, copper and brass etc. Benefits with the large runs with the fast production and results in the most effective process.

The sheet metal fabrication offers the following benefits

● No physical contact with the metal sheet

● Precision material processing

● No sheet metal warping due to the avoidance of heat zone

● Capability to cut complex contours

● Ability to handle intricate or detailed shapes

● Providing the quiet operation

● Maintaining a clean edge to the operation

● Producing the narrow kerf

Also, it offers a variety of benefits. Affordable prices, high efficiencies, fast speed, higher quality cuts and the best possible precision for the industry.

● An Affordable Price

Choosing a fiber laser cutting machine is one of the best ways to keep the budget in check. It utilizes computer numerical control (CNC) for cutting the metals with an automated process. The computer controls the laser entirely so there is no need for an operator to perform the operation. Simply have to feed the instruction & design file to the system. Once the specifications entered are finished, the computer performs the rest.

Additionally, lasers do not dull and the fiber laser emits a focused beam of light that can cut. A traditional cutting machine requires additional maintenance and repair costs. Therefore, it is both easier & more efficient than traditional cutting and has a lower cost.

● Efficiency

The cutting process is faster and more precise than any conventional method which processes the materials shortly. The speed of the laser is determined by the complexity and tolerances of the sheet metal. The speed of lasers can be increased according to the material requirement. The automated nature of laser cutters also allows them to work when operators are not present. With this 24/7 capability, it has become even more efficient and quick for processing.

● Quality Enhancement

The benefits of CNC automation reducing lead times, computer-controlled processes also produce minimal variation when compared to non-automated ones. It results in a lower defect rate and higher quality cutting.

● High Levels of Precision

The sheet metal laser cutting machine has the capability to process extremely fine detail, make the smallest possible cuts within the tightest tolerances. It is a good option when intricate cuts are needed, producing clean and precise edges. Additionally, there is minimal distortion, melts the materials, is appropriate for cutting sheets of metal and accurate due to the precision.

Summary

For sheet metal cutting projects, CNC laser cutting machines provide outstanding performance with shorter lead times that are made possible by laser automation and low maintenance requirements. Additionally, it produces levels of precision that cannot be achieved with other methods. As a result, high-quality cutting is achieved at a low cost with a short production time.

It has massive advantages over alternative metal cutting methods that give the power to help businesses produce results on an unprecedented scale. As a constantly developing field, fiber lasers continue to offer more benefits as it grows. The latest technology assists in getting the best quality cut, at rapid speeds and at an affordable price.

We have recently supplied the machine from 3 kW to 40 kW which has bolstered our laser cutting services. This post explains the main benefits of fiber laser cutter, continuously adapting to power up and add value to every business it encounters.

The advantages of laser cutting over alternative methods include

● Cuts the material with ease

● Reliable and fast machinery for rapid turnaround

● Uses less energy when processing

● Cuts through the thickest of metals including mild steel

● Cut complex shapes with precise detail

● Produces the flawless edge finish

● Quality Output

Plasma or water traditionally acts as more cost-effective than laser cutting but those methods don’t provide anywhere near the quality of a laser cut. The improvements in power, efficiency and technology mean the machine can match or even supersede the value of alternative methods. Works depending on the intricacies of the requirement, processing quicker and cleaner with less heat distortion. After the processing, it is easier to work with and ready for our customers to use!

● Material Capabilities

Waterjet cutting is another alternative for metal cutting solutions but there is no significant overlap between laser & waterjet cutting until recently. It is historically used for different cutting methods depending on the metal.

● Zero Handling

Zero handling of the machine has to be one of the greatest benefits of laser cutting with Business Point International, UAE. The programming assists in getting the perfectly finished metal without any scraping or flake-off. It makes the most complicated jobs easy, even programming the machine to use “part removal” and continue cutting until the job is done.

The automation really benefits when parts are cut with a two-sided finish with perfectly finished metals. The autoloader means the sheet enters and exits the machine without any scraping of the underside. It makes the processing easy and can provide a quality second to none!

● Metal Cut To Size

We are proud to employ a long-serving team of laser cutting experts for the material processing industry. It is the key to the investments, made to serve the customers and provides every solution. The machine listens to the individual needs and technology to achieve what is required by adapting the services to suit their brief. This machine assists larger engineering divisions working with a wider range of requirements such as construction, marine, manufacturing and medical industries. The world-class equipment can process all including metal materials and thicknesses.

Wrapping Up

At Business Point International in the UAE, we are the frontier of providing our customers with the latest innovations in sheet metal laser cutting machine to ensure paramount performance at the quickest speed. It is coupled with powerful machinery, enabling production of high-quality work with ultra-fast turnarounds at competitive prices. It can handle large batches & high-volume jobs with ease, helps to make the dream project a reality and assists in achieving the results the industry requires. The advantages are clear, enabling an economic and cost-effective solution that offers precise cuts. The advanced programming expertise, the possibilities for metal cutting are almost endless! With the dynamic approach tailored to the requirements, transforms the project and generates unique results. It really is all in the details! Contact us to request a consultation or quick quote today!