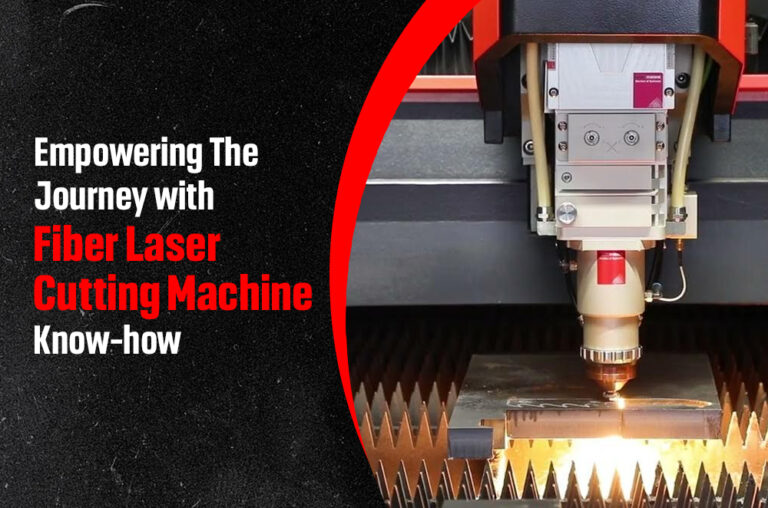

Fiber laser cutting machines have revolutionized the material manufacturing and metalworking industries highly. It is offering quicker cutting speeds than conventional methods, high efficiency, reducing production times and enhancing overall productivity. Ensures superior precision, allowing for intricate and complex designs with impeccable edge quality. This high level of accuracy translates to minimal material wastage and contributes to cost savings. The fiber laser is incredibly versatile which is capable of handling a wide range of materials such as stainless steel, carbon steel, copper, aluminum, nickel, manganese & other metal types. Energy-efficient, consuming less power compared to other cutting technologies, leading to reduced operational costs and environmental benefits. Lastly, their compact design and low maintenance requirements provide the preferred choice for various industries.

● Fiber Laser Source

A fiber laser cutting machine utilizes a fiber laser source that generates the concentrated beam of laser for precise material processing. Unlike traditional CO2 lasers, the fiber laser produces the highly efficient laser bean, delivering superior beam quality, faster cutting speeds and reduced maintenance requirements. It allows for easy integration into various cutting systems and excels in cutting a wide range of materials, Indispensable for industries such as manufacturing, automotive, and aerospace to achieve intricate cuts with high accuracy.

Advantages

It gives higher efficiency, converting a greater percentage of input energy into laser output. Results in reduced power consumption and operating costs with superior beam quality. Enable the finer precise cut, have a longer lifespan, require minimal maintenance and ensure faster cutting speeds. It is the preferred choice for industries seeking high-performance, cost-effective and versatile cutting solutions.

● Servo Motors and Drives

The servo motor plays an important role in the operation of fiber laser cutting machines. It has precise control over the motion of the laser cutting head, assists with accurate positioning and rapid movement. Generates high torque and follows intricate paths with minimal error. The advanced drive system gives consistent speed and positioning accuracy to achieve intricate designs. The integration of servo technology enhances overall processing, reduces material waste and facilitates the production of complex components. Constantly monitor & adjust performance, ensuring optimal cutting results across various materials and integral to the reliability of modern fiber laser cutting processes.

Advantages

It offers unparalleled precision & control, the high torque capabilities ensure swift and accurate positioning which is crucial for intricate cutting tasks. The consistent speed and torque across varying loads to maintain cutting quality & efficiency. Facilitates rapid acceleration and deceleration to optimize cycle time and enhance productivity. Allowing for real-time adjustments and ensuring optimal performance. The reliability of the servo motor coupled with low maintenance requirements results in reduced downtime and operational costs. It elevates the performance, accuracy and reliability of precise manufacturing applications.

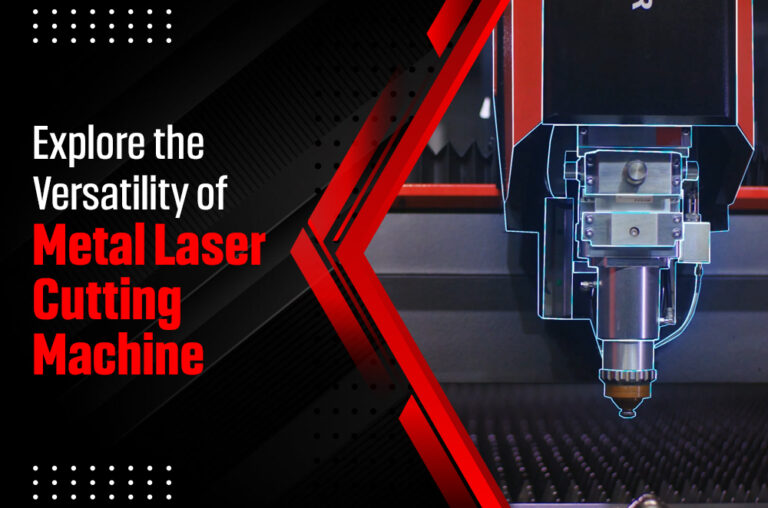

● Fiber Laser Head

The fiber laser head is responsible for delivering the laser beam to the workpiece with precision. The head consists of various components including focusing lenses, protective nozzles and possibly a height sensor. The focusing lens delivers a concentrated laser beam to a small spot size, ensuring efficient material removal and high-quality cuts. Protective nozzles surround the lens shielding it from debris and gasses produced during the operation. It has a prolonged lifespan, maintaining cutting accuracy. Incorporated height sensors to maintain a constant distance between the head & the workpiece and compensate for any variations in material thickness or surface irregularities. The head design & functionality determines the machine’s performance, precision and the quality of the finished products.

Advantages

The head plays the pivotal role in achieving high-quality cuts with precision and the design ensures efficient beam delivery to the workpiece. Assisting with the consistent and uniform cutting. The focusing lens within the laser head gives the concentrated beam, facilitating detailed cuts even on thin materials. The advanced height sensors give optimal focal distance, compensating for material variations. Overall, it enhances the efficiency for achieving superior cutting results.

● Machine Frame

The machine body frame serves as its entire structural backbone, providing stability, rigidity and support to all other components. It is constructed with robust materials, involves the annealing treatment to increase the ductility, operates with minimal vibrations and is essential to achieve high-precision cuts. The design incorporates gantry to support the laser head’s movement across the worktable. The rigidity of the frame prevents any unwanted flexing or distortion. The frame’s durability helps for the machine’s longevity & reliability and withstands the stresses & forces generated during operation. Facilitates ease of access for maintenance & component replacement and the machine remains operational and efficient throughout its lifecycle in diverse industrial settings.

Advantages

It serves as a foundational structure, ensuring stability, minimizing vibration and supporting the bridge structure. In essence, the frame is fundamental in ensuring the overall performance and longevity of the fiber laser cutting machine.

● Rack and Gear System

The helical rack and gear system translates the rotational motion of the machine’s servo motors into precise linear movement. Resulting in smoother & quieter operation, minimizing backlash and enhancing overall motion accuracy & repeatability. Delivers the precise and synchronized movement of the laser cutting head. Distributing the load and extending the system’s lifespan. This mechanism enables rapid acceleration, facilitating faster cutting speeds without compromising on precision. The integration enhances the performance and reliability of various industrial applications.

Advantages

It provides motion control, reducing operational noise and angled teeth engagement which is smoother compared to traditional straight-toothed gear. Designed to minimize the backlash, repeatable positioning and crucial for high-accuracy cuts. This configuration distributes the loads evenly, reducing wear and extending system longevity. Handles handle rapid acceleration and deceleration enhancing cutting efficiency. Optimizes the direction of the movement, constant performance in fiber laser cutting machines.

● Planetary Gearbox

The gearbox provides versatile speed reduction and torque multiplication capabilities. This compact design allows for efficient power transmission in a confined space. It serves to adjust & optimize the rotational speed of the servo motors to achieve the desired cutting speeds and torque levels. The configuration gives balanced load distribution across the gear and ensures smoother operation. Has the ability to handle varying loads and speeds makes it ideal for adapting to the dynamic requirements. incorporating to achieve high levels of precision and reliability makes it indispensable in modern manufacturing environments.

Advantages

The multifaceted facility of the gearbox benefits from power transmission and control. The compact design efficiently converts and optimizes rotational speeds. Has precise adjustments tailored to cutting requirements. The balanced distribution of loads assures smooth operation and enhances the machine’s adaptability to diverse cutting tasks. The robust construction gives durability or a consistent cutting process. Amplifies the machine’s efficiency and adaptability making it a vital component.

● Shuttle Table

An integrated shuttle table in a fiber laser cutting machine enhances operational efficiency. Allowing simultaneous material loading/unloading and cutting processes. The table design features inside the chamber processing the material and the other side is positioned outside for material handling operations. Once the cutting cycle completes, the shuttle system swiftly exchanges the tables. The machine minimizes downtime and maximizes productivity. The seamless transition operation enables operators to unload finished parts and load new material without interrupting the cutting process. This design can improve workflow management, optimize machine utilization and help in a high-volume production environment. Gives continuous operation, consistent output quality, enhanced versatility, high productivity and meets the demands of diverse industrial requirements with precision.

Advantages

The shuttle table in a fiber laser cutting machine revolutionizes material handling and processing efficiency. It incorporates dual work surfaces and enables seamless transitions between cutting & material loading/unloading processes. One table operates within the cutting chamber and the other facilitates handling the material outside. It optimizes machine utilization, ensuring continuous production flow and maximizing throughput. Enhances workflow management and allows operators to prepare materials for the next cycle without interrupting the ongoing cutting process. Boosts productivity, elevates operational efficiency, reduces idle times, and streamlines production processes for modern manufacturing.

Choosing to purchase a fiber laser cutting machine emerges as a strategic and forward-thinking decision for the material processing industry. The reputation of the business is built on a foundation of reliability and customer-centric service. Partnering with Business Point International in the UAE promises enhanced efficiency, comprehensive after-sales support, ensuring uninterrupted operations and minimized downtime. This machine’s expertise ensures that clients receive tailored solutions that align with specific manufacturing needs and objectives. Additionally, the commitment to innovation for the company gives the benefit from advancements in laser cutting technology, ahead in a competitive market landscape. In conclusion, investing in a fiber laser company from BPI elevates operational capabilities, also signifies a commitment to excellence and future growth.